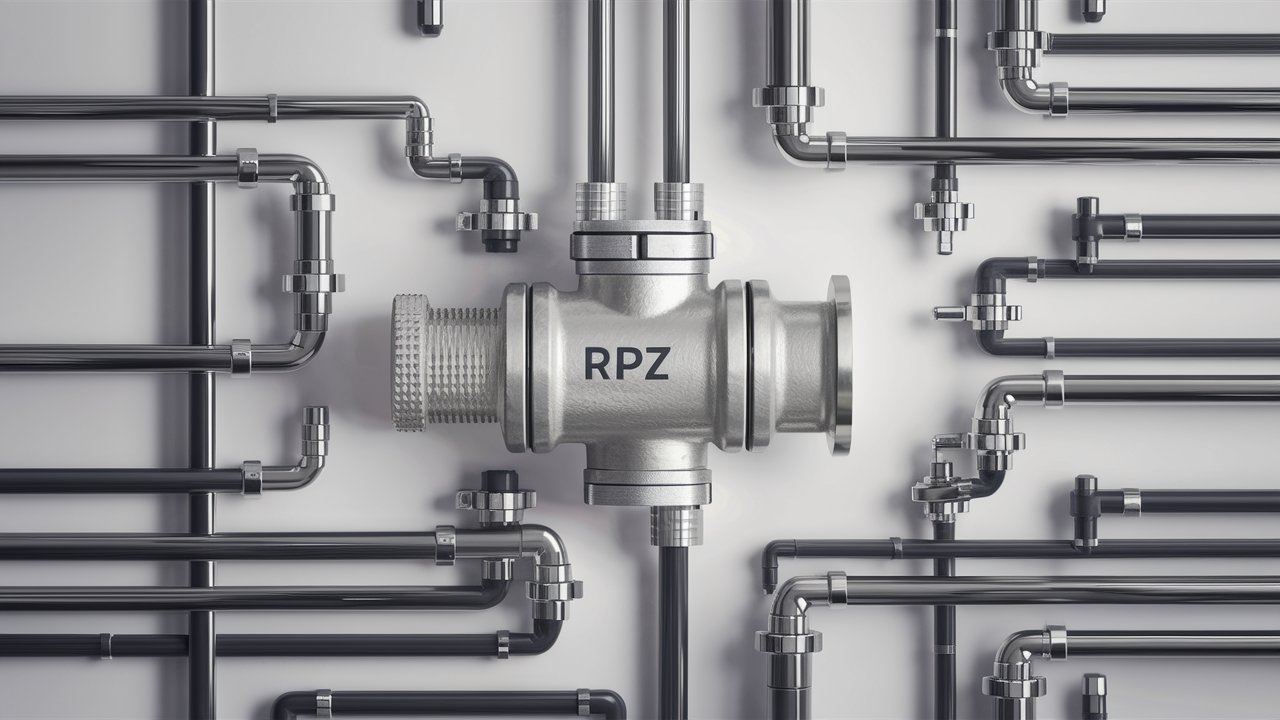

RPZ valves, or Reduced Pressure Zone valves, are critical components in plumbing systems designed to prevent the backflow of contaminated water into the clean water supply. They are essential for maintaining the safety and purity of potable water. An RPZ valve operates by creating a zone of reduced pressure to ensure that any backflow is contained and cannot enter the clean water supply. This type of valve is highly effective in protecting water systems from potential contamination caused by backflow events.

RPZ valves are commonly used in various applications where the risk of backflow is significant. They are designed to handle high-risk situations and ensure that any potential contaminants are safely contained. By providing a reliable means of preventing contamination, RPZ valves play a vital role in safeguarding public health and maintaining the integrity of water systems.

How Does an RPZ Valve Work?

An RPZ valve functions by using a two-chamber design with a pressure differential to maintain a zone of reduced pressure. The valve has two check valves separated by a pressure-relief valve. The first check valve prevents backflow from entering the clean water supply, while the second check valve and pressure-relief valve work together to create a reduced pressure zone. This ensures that any potential contaminants are contained and do not reach the potable water supply.

Why Are RPZ Valves Important?

RPZ valves are crucial for preventing cross-contamination in water systems. Without these valves, there is a risk that contaminated water could flow back into the clean water supply, posing health hazards to consumers. By maintaining a reduced pressure zone, RPZ valves effectively isolate and contain any contaminants, ensuring that the water supply remains safe and clean.

In addition to their health and safety benefits, RPZ valves help to comply with plumbing codes and regulations. Many jurisdictions require the installation of RPZ valves in specific high-risk scenarios to meet legal standards for water safety. This makes RPZ valves not only a preventive measure but also a necessary component for regulatory compliance in various applications.

Where Are RPZ Valves Usually Installed?

RPZ valves are typically installed in areas where the risk of backflow is high. They are essential for maintaining the safety of the water supply in several critical applications, including large boilers, irrigation systems, and fire suppression systems.

1. Large Boilers

In large boiler systems, RPZ valves are used to prevent any potential backflow of water from the boiler into the main water supply. Boilers often involve the use of chemicals and other substances that could contaminate the water supply if backflow occurs, making RPZ valves a crucial safety feature.

2. Irrigation Systems

Irrigation systems often use water that may contain fertilizers, pesticides, or other chemicals. Installing RPZ valves in these systems helps to ensure that any potential contaminants are kept out of the potable water supply, protecting public health and the environment.

3. Fire Suppression Systems

Fire suppression systems require large volumes of water, which may be mixed with chemicals or foam concentrates. RPZ valves are installed to prevent the backflow of these substances into the potable water supply, ensuring that the water used for firefighting does not contaminate the drinking water system.

Are RPZ Valves Good At Preventing Contamination?

Yes, RPZ valves are highly effective at preventing contamination. Their design is specifically intended to handle high-risk situations and ensure that any potential contaminants are contained within the reduced pressure zone. By maintaining a zone of reduced pressure, RPZ valves provide a robust barrier against backflow, making them a reliable choice for safeguarding water systems and protecting public health.